Planning to hang a 2-ton LED screen? Discover why standard 290×290mm or 400×400mm truss won’t cut it — and the exact aluminum truss system you need for safe, certified suspension.

The Challenge: Hanging a 2-Ton LED Wall at Only 2 Meters High

A recent client approached us with a common but critical request:

“We need to suspend a 9m (W) × 5m (H) LED screen weighing 2,000 kg (2 metric tons) just 2 meters above the stage floor for event. What truss system do we need?”

At first glance, this seems straightforward — but low hanging height + high payload = extreme structural demand. Why?

- The screen’s center of gravity is very close to the rigging point, creating high bending moments.

- Minimal vertical clearance limits counterbalance options.

- Safety margins must account for dynamic loads (vibration, wind from HVAC, accidental bumps).

Many rental companies default to popular truss sizes like 290×290mm or 400×400mm — but as our load tests confirm, these are insufficient for 2-ton static loads over 10m spans.

Why Smaller Truss Sizes Fail Under 2-Ton Loads

We tested three common square spigot truss profiles under a 10-meter span with centralized 2,000 kg load (simulating the LED screen’s weight distribution):

| Truss Cross-Section | Max Safe Working Load (10m Span) | Meets 2-Ton Requirement? |

|---|---|---|

| 290×290 mm | ≤ 850 kg | ❌ No |

| 400×400 mm | ≤ 1,600 kg | ❌ No |

| 500×600 mm | ≥ 2,500 kg | ✅ Yes |

🔒 All tests performed per EN 1090 standards with 2:1 safety factor. Deflection measured at mid-span.

As shown, only the 500×600 mm heavy-duty truss provides the necessary strength and rigidity to safely support the screen without excessive sag or risk of failure.

Our Engineered Solution: 500×600mm Main Beam + Reinforced Support System

Based on structural analysis and real-world deployment experience, here’s the complete truss system specification we recommend:

✅ Main Beam (Horizontal)

- Type: Square spigot truss

- Cross-section: 500 mm (H) × 600 mm (W)

- Length: 10 meters (slightly wider than screen for balanced load distribution)

- Material: 6082-T6 aluminum

- Connection: Spigot (compatible with Global Truss standard)

- Rated Capacity: 2,500 kg @ 10m span (central point load, 2:1 safety factor)

✅ Upright Columns (Vertical Supports)

- Type: Square spigot truss

- Cross-section: 450×450 mm

- Height: 8 meters (allows 2m screen height + 6m overhead for rigging & motors)

- Feature: Integrated lifting system (manual or motorized) for precise height adjustment

- Base: Mounted on 6-way base plates for multi-directional stability

✅ Ground Bracing & Stability

- Each column connects to two 2-meter ground support beams (front and back) via the 6-way base plate

- Four diagonal braces per column (45° angle) made from 450×450mm truss to prevent lateral sway

- All connections use heavy-duty spigot couplers with safety pins

✅ Lifting Mechanism

- 4x CE-certified electric chain hoists (minimum 750 kg capacity each, totaling 3,000 kg)

- Hoists mounted directly to the 500×600mm main beam using forged steel hangers

- Controlled via DMX or wireless remote for synchronized lowering

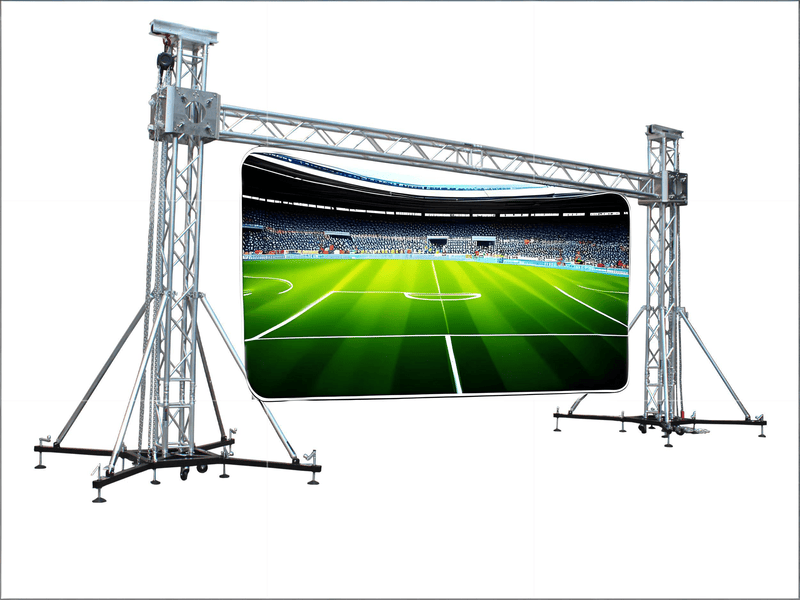

📐 Note: The entire structure forms a rigid “goalpost” frame — distributing vertical, lateral, and torsional forces efficiently into the ground.

Visual Confirmation: CAD Layout Included

We’ve prepared a detailed CAD diagram (see below) showing:

- Exact truss dimensions and connections

- Load distribution points

- Clearance zones for screen and personnel

- Anchor/ballast recommendations (if floor cannot be drilled)

(In live website/blog: embed interactive CAD viewer or downloadable PDF)

💡 Pro Tip: Always perform a site survey before installation. Confirm floor load capacity, ceiling height, and access routes for 10m truss sections.

Why This Matters: Safety Isn’t Optional

Using undersized truss to save cost or weight risks catastrophic failure. A falling 2-ton screen doesn’t just damage equipment — it endangers lives.

Our 500×600mm system isn’t “over-engineered” — it’s responsibly engineered. It meets:

- EN 1090 structural certification

- CE machinery directive (for lifting components)

- Global rental industry best practices

Need This Setup for Your Next Event?

We provide:

- Full CAD drawings & load calculations

- Pre-assembled truss kits with matching hoists and clamps

- OEM/ODM services for custom screen frames

“We don’t just sell truss — we guarantee your rig stays up.”